Science Roundup: Trending in Food Microbiology

Several articles got our attention this week.

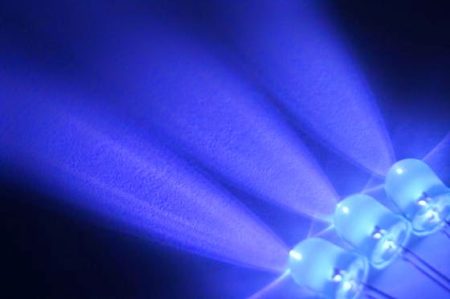

Elevated Inactivation Efficacy of a Pulsed UVC Light-Emitting Diode System for Foodborne Pathogens on Selective Media and Food Surfaces

Applied and Environmental Microbiology published an article by Do-Kyun Kim and Dong-Hyum Kang on action required to replace short- wavelength ultraviolet (UVC) light that is being used extensively to disinfect surfaces in the food industry. By 2020 the use of use of low-pressure mercury lamps will be discontinued and a new source of UV will be required.

Applied and Environmental Microbiology published an article by Do-Kyun Kim and Dong-Hyum Kang on action required to replace short- wavelength ultraviolet (UVC) light that is being used extensively to disinfect surfaces in the food industry. By 2020 the use of use of low-pressure mercury lamps will be discontinued and a new source of UV will be required.

This study investigated the use of a UV light  -emitting diode (UV-LED) as an alternative. The study found that a combination of 20-Hz frequency and 50% duty ratio for pulsed UVC-LED irradiation achieved 4- to 5-log-unit reductions of Escherichia coli O157:H7, Salmonella enterica serovar Typhimurium, and Listeria monocytogenes.

-emitting diode (UV-LED) as an alternative. The study found that a combination of 20-Hz frequency and 50% duty ratio for pulsed UVC-LED irradiation achieved 4- to 5-log-unit reductions of Escherichia coli O157:H7, Salmonella enterica serovar Typhimurium, and Listeria monocytogenes.

The Use of Shotgun Metagenomic Sequencing for Mesophilic Spore-formers Identified in Whey Powder

Spore formers can cause spoilage in the dairy industry and the current agar based methodology is slow, and have limitations in sensitivity and specificity. Applied and Environmental Microbiology published an article by A. J. McHugh, C. Feehily, J.T. Tobin, M.A. Fenelon, and P.D. Cotter, describing a new method to detect spoilage spore formers in dairy powders using Shotgun metagenomic sequencing approach.

Shotgun metagenomic sequencing allows detection and identification of possible pathogens and spoilage bacteria in parallel. It also provides a means to study unculturable microorganisms. Three groups of mesophilic spore-formers, (Bacillus cereus, Bacillus licheniformis/Bacillus paralicheniformis, and Brevibacillus brevis), dominated the spore population of whey powder. Total thermophilic spore-former taxonomy was considerably different from mesophilic taxonomy. The study shows potential for this technology, to facilitate the detection of spore-formers present in dairy powders.

A nano-carrier platform for the targeted delivery of nature-inspired antimicrobials using Engineered Water Nanostructures for food safety applications

Food Control (Vol 96, February 2019, Pages 365-374) published an article by N. Vaze, et. al describing a new nano-carrier technology, for the delivery of antimicrobials for sterilization of surfaces in the food industry, using Engineered Water Nanostructures (EWNS).

iEWNS (the ‘i’ denoting the active ingredient) that are: i) engineered to have a nanoscale size; ii) have excessive electric surface charge, and iii) contain both the reactive oxygen species (ROS) formed due to the ionization of deionized (DI) water, and the active ingredient is used in their synthesis. A number of nature-inspired antimicrobials, such as H2O2, lysozyme, citric acid, and their combination, were used to synthesize a variety of iEWNS-based nano-sanitizers. The technology achieved 5-log reductions of E. coli in just minutes of exposure time with hydrogen peroxide, citric acid, and lysozyme.

This aerosol-based, yet ‘dry’ intervention approach using iEWNS nano-carrier platform offers advantages over current ‘wet’ techniques that are prevalent commercially, which require grams of the AI to achieve similar inactivation, leading to increased chemical risks and chemical waste byproducts. Such a targeted nano-carrier approach has the potential to revolutionize the delivery of antimicrobials for sterilization in the food industry.

Application of X-ray for inactivation of foodborne pathogens in ready-to-eat sliced ham and mechanism of the bactericidal action

Food Control (Vol 96, February 2019, Pages 343-350)published an article by Ga-Lam Cho and Jae-Won Ha showing the effect of X-ray irradiation on reducing pathogen (Salmonella, E. coli o157:H7, and Listeria monocytogenes in post-packaged ready-to-eat (RTE) deli food products.

Surfaces of samples were inoculated by a cocktail of the pathogens. Irradiation with 0.8 kGy of X-rays significantly reduced Salmonella Typhimurium, E. coli O157:H7, and Listeria monocytogenes in RTE ham slices by 5.7, 7.2, and 6.9 log CFU/g, respectively. X-ray irradiation applied up to 0.8 kGy did not negatively affect product quality attributes such as color and texture of the sliced ham products. The study suggests that X-ray Irradiation can be used in RTE products, post-packaging, to reduce pathogens.