Environmental Monitoring and FSMA

Why Monitor the Environment?

The requirement for environmental monitoring is mentioned under CFR 21 section 117.165 “Current Good Manufacturing Practice, hazard analysis, and risk based preventative controls for human foods”. It requires a facility to conduct validation and verification activities, as appropriate to the nature of the preventive controls, to ensure a clean facility.

The requirement for environmental monitoring is mentioned under CFR 21 section 117.165 “Current Good Manufacturing Practice, hazard analysis, and risk based preventative controls for human foods”. It requires a facility to conduct validation and verification activities, as appropriate to the nature of the preventive controls, to ensure a clean facility.

The validation efforts are based upon a safety plan that is related to hazard analysis. However, because of differences between facilities, the FDA does not define specific factors associated with developing an environmental monitoring program. Instead it is stated that they are required to “be adequate for their intended purpose.”

Environmental monitoring can include monitoring of indicator organisms such as aerobic plate count (APC) but can also include testing of food pathogens such as Listeria or Salmonella. In facilities that are producing ready-to-eat (RTE) items, their environmental monitoring program will be much different from one that involves foods that will be cooked or further processed before being consumed.

For RTEs it is critical that environmental pathogens are controlled to ensure that they do not contaminate the product. For these types of products, perhaps the greatest use of testing lies in environmental pathogen monitoring.

A non-pathogenic indicator organism may be used as a surrogate for a pathogen only if there is scientific evidence to support a direct relationship between the detection of the surrogate and the presence of a specific pathogen. To date, the only proven predictive surrogate is Listeria innocua or Listeria spp. which is taken as a direct indicator of the presence of L. monocytogenes.

Environmental testing typically entails taking microbiological samples of food contact surfaces or nearby areas, testing for the presence of a pathogen or indicator organism. For dry foods where a raw product or ingredient could be introduced, Salmonella is generally the organism of concern. For RTE foods processed under wet conditions or environments, the organism of concern is generally Listeria monocytogenes.

Role of ATP Monitoring:

One of the most common tests for cleanliness is that of Adenosine triphosphate (ATP). Its detection after the manufacturing equipment has been cleaned, is an indicator that food debris, bacteria or other organisms have been left behind and the cleaning process was not completed. ATP can be an indicator of the amount of cellular-based organic residue left on a surface which could potentially contaminate the next manufacturing run.

Environmental monitoring programs can be used to identify hotspots, check the validity of food safety programs and indicate trends. It can be used to control, and find trending out of control (early warning), or requiring corrective action. It can give a rapid indication of the sanitary condition of the lines.

If environmental testing detects an environmental pathogen or an indicator organism on a product contact surface, then the facility may consider conducting end-product testing to determine if the product was contaminated.

For an FDA Food Safety Plan, the focus is on pathogens, and making sure that pathogens are not in the finished product. Therefore, an environmental monitoring program used to verify sanitation and other environmental controls must seek out pathogens.

How to decide if pathogen environmental monitoring programs (PEMPs) is required?

Not all food manufacturers are required to test the environment for pathogens. To determine if PEMP is necessary and which organism to monitor, a thorough risk evaluation should be conducted.

Timothy Freier and Joseph Shebuski write about the fact that in ready-to-eat (RTE) perishable refrigerated products (e. g., deli-meat, salads, certain soft cheeses, cooked seafood, fresh-cut produce and hot dogs)L. monocytogenes has the greatest risk. In RTE that are shelf stable (e.g., nuts, nut butters, soy products, dry pet food, breakfast cereals, snacks, chocolate), Salmonella PEMP has the best value.

Salmonellosis has also been linked to raw unpasteurized products such as meat, poultry, eggs, dairy, grains, spices, and produce. However, these product contamination events were caused by the inherent presence of the pathogen in the raw products, and not by contamination originating from food manufacturing facilities. Salmonella PEMP is typically not necessary in facilities manufacturing these types of non-RTE products.

Evaluation of Results

The most important element of PEMP is the result evaluations, which should be done in a timely manner. If positives are found the results should be reviewed and corrective action must follow.The corrective action should target the root cause of the contamination. It should not only include re-cleaning or re-sanitizing of the areas found positive. It should include activities to achieve a permanent fix such as facility modification and process changes.

The 4 Zones

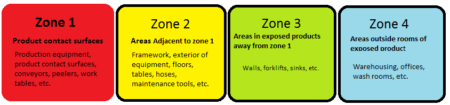

Zones are defined based on the probability of product contamination if a pathogen is present in the zone.

A pathogen in zone 1 is certain to contaminate the product. For inspections focusing on the presence of Salmonellae, food contact surfaces are normally not sampled. In contrast, for inspections focusing on detection of Listeria monocytogenes, sampling of food contact surfaces is essential. Many companies do not test zone 1 because it is likely too late for prevention and will likely mean a need to recall the product.

Zone 2 , the areas directly adjacent to Zone 1. For investigations focusing on Salmonellae, this is the area where environmental contamination is most likely to directly affect safety of the product and consequently it is the main focus for PEMP.

Zone 3 is the area immediately surrounding Zone 2. Zone 3, if contaminated with a pathogen, could lead to contamination of Zone 2 via actions of humans or movement of machinery.

Zone 4 is the area immediately surrounding Zone 3, if contaminated with a pathogen, could lead to contamination of Zone 3 via the actions of humans or machinery.

As mentioned above many companies do not usually test Zone 1 because it is likely too late for prevention and will likely mean a need to recall the product. The sampling should focus on Zone 2 because it has greater access to the food product and warm and wet areas that encourage bacterial growth. Zone 3 is tested less that zone 2. Very few, if any, environmental samples should be taken from Zone 4.

Any pathogen detection in zones 1-3 need to be addressed by corrective action.

Final thought

The food industry is doing more PEMPs because the regulators are testing the environment in the plans. The industry needs better understanding on how pathogens move in a plant to prevent their spread.

If a result comes back positive for a foodborne pathogen, production of the product may need to be put on hold and more testing may need to be done. In some cases, the product may even need to be reprocessed or destroyed completely.