Detection of bacterial growth and Biofilm formation in pipelines made easy

By Giovanni Pavanello

The Biofilm Problems

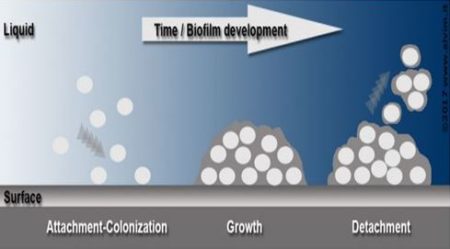

On the surfaces that are in contact with water, a “biofilm” layer of microorganisms that are contained in a matrix (slime layer) can be formed. It is as a complex community of microorganisms, embedded in self-created extracellular polymeric substances (EPS). The biofilm is a microbial population adherent to each other and to the surfaces or interfaces enclosed in the matrix. Their presence in manufacturing pipelines can be responsible for a wide range of water quality and operational problems.

A Biofilm layer can form on any surface, even in extreme conditions (e.g., very high and very low pH values and temperature, in radioactive waters, even in space stations), and it causes a variety of problems:

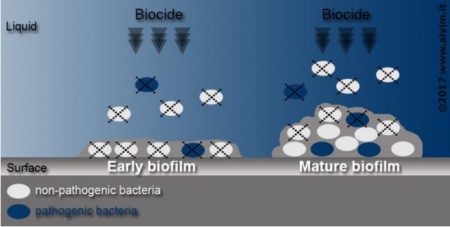

- Increase in the risk of pathogens – biofilm is the ideal environment for the proliferation of harmful bacteria by offering shelter and food;

- Decrease in thermal efficiency of heat exchangers – for example, the biofilm is more insulating than calcium carbonate;

- Microbiologically influenced corrosion (MIC) – also known as bacterial corrosion, it accounts for billions of dollars of industrial damages all over the world.

Large amounts of chemical substances (sanitizers, biocides, and disinfectants) are usually employed to prevent biofilm development in industrial piping systems. However, often they do not provide the expected results. In most cases, Clean-In-Place (CIP) and sanitation treatments are applied out on a regular basis (daily, or weekly) or when visible problems arise. The real need for neither the treatment nor its effectiveness is verified.

It is important to note that it is usually hard to take representative samples (“swabs”) from internal pipe surfaces. Standard plate counts applied to water samples are of limited use. Indeed, it is well known that bacterial growth on pipe surfaces is mostly unrelated to the presence/number of bacteria in the water.Planktonic (free-floating) bacteria attach to the pipes by the production of ESP; they multiply and form a mature biofilm, stabilizing the microcolony from environmental stress. Therefore, most bacteria live in biofilms, not free in the water.

Bacteria embedded in the biofilm are more difficult and expensive to eliminate, than free-floating planktonic bacteria. The extracellular substances (EPS) increase the bacterial resistance to external agents, by up to 1000x. As the biofilm matures, the ESP matrix becomes thicker. Thus it is much more resistant than an early-stage one. Sanitation and cleaning treatments should be applied on early-phase biofilm, to obtain the best results.

Moreover, when the biofilm is mature, its outermost layers tend to detach and float away. In these cases, it increases the likelihood of biofilm formation in other areas of the piping system.

The ALVIM Biofilm Monitoring System

Innovative technology for the detection of biofilms was developed by ALVIM, an Italian Company, in collaboration with the Italian National Research Council.

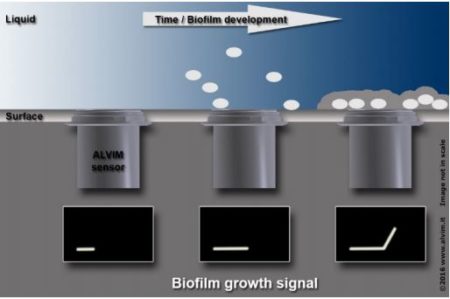

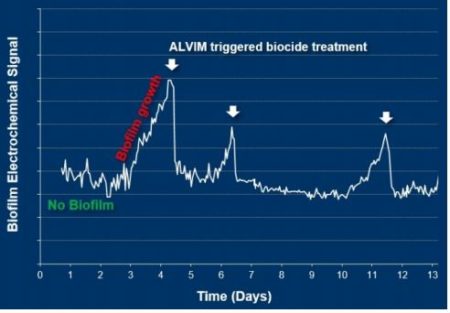

By measuring bacteria bio-electrochemical activity (a phenomenon known as “ennoblement” or “cathodic depolarization”), the ALVIM technology detects biofilm formation since its first phases, online and in real time. The technology allows checking the effectiveness of CIP and sanitation treatments, without the need for water sampling and lab analyses. An example, from a reverse-osmosis (RO) system, is illustrated in the graph on the right. As it can be seen in the figure, the user can decide when to apply CIP, checking in real time if biofilm was actually removed.

An example, from a reverse-osmosis (RO) system, is illustrated in the graph on the right. As it can be seen in the figure, the user can decide when to apply CIP, checking in real time if biofilm was actually removed.

The system helps in keeping track of bacterial settlement and growth inside water lines, tanks, and other surfaces in contact with the water and other liquids allowing checking, simultaneously, the efficacy of sanitation treatments.

The ALVIM probes are more specific than other sensors since they detect bacterial fouling (biofilm formation), not other kinds of deposit, such as minerals, proteins, fats, etc. This is extremely important since different fouling types require different treatments. It is important to emphasize that the ALVIM sensors are very sensitive to the detection of biofilm in its initial colonization phase, the best time to apply CIP and sanitation treatments.

ALVIM biofilm probes are currently used worldwide, in applications ranging from Cooling Towers to Food and Beverage, Paper Production, Oil and Gas and others, including large international Companies like Total, GDF Suez (ENGIE) and Danone.

The Massachusetts Institute of Technology (MIT) used ALVIM probes, in a Project regarding water distribution systems, and the European Defence Agency (EDA) indicated ALVIM Technology as a promising solution to the cleaning of biofilms. Overall, the ALVIM Technology allows for a simple and flexible approach to biofilm monitoring, considering different applications such as:

- Analysis and characterization of biofilm growth;

- Assessment and comparative evaluation of different chemical biocides, CIP and sanitation treatments;

- Real-time, continuous monitoring of water treatment systems;

- Automatic and/or remote control and optimization of sanitation treatment;

- Effective prevention of pathogens, like Legionella, Listeria and Staphylococcus

More info available at: http://www.alvimcleantech.com/cms/en/biofilmsensors