Biofilm and food safety: What is important to know?

Part 2: What are the best control strategies?

Dr. Bassam A. Annous, Eastern Regional Research Center, USDA–ARS–NEA, and Dr. Ruth Eden, BioExpert.

Biofilms are usually formed in a wet environment and in the presence of nutrients. Once biofilms are formed, the cleaning of the food and food contact surfaces becomes more difficult to remove the extracellular polymeric substances (EPS). Therefore, prevention of biofilm formation, using regularly scheduled cleaning and disinfecting protocols is an important first step in preventing cells from attaching and forming biofilms on surfaces.

Biofilms are usually formed in a wet environment and in the presence of nutrients. Once biofilms are formed, the cleaning of the food and food contact surfaces becomes more difficult to remove the extracellular polymeric substances (EPS). Therefore, prevention of biofilm formation, using regularly scheduled cleaning and disinfecting protocols is an important first step in preventing cells from attaching and forming biofilms on surfaces.

High-temperature washing can reduce the need for the physical force required to remove biofilms. Chemical cleaners suspend and dissolve food residues by decreasing surface tension, emulsifying fats, and denaturing proteins. The mechanism by which cleaning agents remove EPS associated with biofilms has not been determined.

Fruit and Vegetable Surfaces

Conventional methods of washing fresh produce with hypochlorite or other sanitizing agents cannot assure microbial safety because they can only achieve 1-2 log reduction. This is because of many enteric pathogens, such as Escherichia coli O157:H7, cause illness at very low infectious doses. For apples, using water, detergents or sanitizing agents, produced a maximum of 3-log (99.9%) reduction in the levels of E. coli. The same treatment using brush washer surprisingly gave less than a 1-log (90%) reduction in E. coli.

A commercial-scale surface pasteurization treatment developed at ERRC (Annous, Burke, and E. Sites), resulted in 4-log (99.99%) reduction in the population of Salmonella Poona on the surface of artificially contaminated cantaloupe. The process involved the immersion of melons in water at 168.8°Fahrenheit for three minutes and then rapidly cooling them. This pasteurization process not only enhances the safety of the fruit but increases the product shelf life by reducing the native microflora that may cause spoilage.

Equipment

Bacterial cells could attach and form biofilms on food processing equipment. The complexity of processing equipment makes it difficult to remove and/or inactivate the bacterial cells in biofilms on food processing surfaces. Since it is extremely difficult to remove these biofilms, food processors should prevent biofilm formation in the first place. This could be done by developing and maintaining a thorough sanitation regiment to help prevent a biofilm layer from attaching to equipment surfaces. Product residues due to spills or debris in the facility support bacterial proliferation and subsequent biofilm formation. Consequently, regular removal of food residues is a key to preventing biofilm formation.

Oko, 2013 suggested three important steps to removing biofilm in a food processing facility:

(i) Cleaning with appropriate sanitizing agents at the required concentrations

(ii) Allowing enough exposure time at the appropriate temperature

(iii) Applying mechanical action

This combination is claimed to penetrate and/or remove the biofilm, and thereby to kill the embedded bacterial cells.

An effective cleaning procedure would break up or dissolve EPS allowing sanitizers to gain access to viable bacterial cells. Alkaline cleaners, especially those with chelators like EDTA, are more effective at removing biofilms than acidic cleaners. Bacteria become far more susceptible to sanitizers once the biofilm matrix has been destroyed, certain enzymes have been proven effective in disrupting EPS matrixes, thus allowing for the removal of biofilms. Recently, novel methods that can serve as alternatives to the current methodology for the disinfection of microbial contamination, such as essential oils and bacteriophages have been successfully tested.

Poly ethylene glycol (PEG) has been shown to inhibit protein adsorption and bacterial attachment to surfaces. Cold plasma was used to deposit PEG-like structures on the surfaces of stainless steel 304 and 316L using 12-crown-4 ether and tri (ethylene glycol) dimethyl ether (triglyme), and ethylene glycol divinyl ether as starting materials.

The plasma modified surfaces significantly reduced biofilm formation by about 80%. When 1% beef hot dog was added to the base medium, biofilm formation on stainless steel 304 was reduced further. Plasma modification of the surfaces did not interfere with the efficacy of cleaning by the chlorinated alkaline detergent.

Newer physical methods of biofilm removal include super-high magnetic fields, ultrasound treatment, high pulsed electrical fields, combined use of high pulsed electrical fields in conjunction with organic acids, and low electrical fields alone or in combination with biocides, such as silver, carbon, platinum, and antibiotics.

Summary

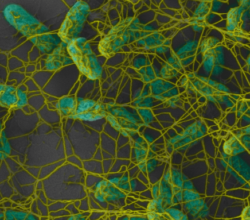

Most bacterial cells in nature exist in biofilms instead of planktonic single cells. Organic and inorganic material (nutrients) attach to surfaces of food and/or equipment and thus creates a conditioning layer whereby microorganisms attach to. Microbial cells then start secreting EPS that further help in the attachment of the biofilm to the food and food processing surfaces. The ESP formation acts as a barrier from sanitizing compounds, making the biofilm stronger. Bacterial activity within the biofilm community can be coordinated through cell-to-cell signaling (Quorum sensing).

Biofilm formation is associated with many foodborne outbreaks. As a result, biofilm has become a problem in food industries as it renders its inhabitants resistant to antimicrobial agents and cleaning agents. The growth of biofilms in food processing environments leads to an increased opportunity for microbial contamination of the processed product. Pathogenic microorganisms in biofilms are the major source of food contaminations.

Biofilms were created by various bacteria on fruit and vegetable surfaces, on various meats, and especially on all types of processing equipment. Once created the biofilm is very difficult to remove, and offer significant protection to the bacteria residing in it.

Breaking up EPS is important in eliminating the biofilm protection and making the bacterial cells more susceptible to the cleaning sanitizers. Several novel methods are available to better clean surfaces containing bacteria in biofilms.