FSMA and the Produce Industry

How did the FSMA started

How did the FSMA started

There were three major events that drove FSMA(Food Safety News).

- In 2006 the large coli O157:H7outbreak linked to spinach, drove the produce industry to push for regulatory change.

- In 2007 the deliberate contamination of wheat gluten with melamine, resulted in dead and sick pets. This event got the attention of the Bush administration due to three factors: It was deliberate, it was in imported food, and it involved China.

- In 2008 the salmonella outbreak, traced back to peanut butter paste manufactured by Peanut Corporation of America, killed 9 people and sickened 714 others, some critically, across 46 states. It was the deadliest salmonella outbreak in recent years which resulted in one of the largest food recalls in American history. The company principals got the toughest jail sentences ever.

FSMA : fresh produce safety rules

The focus of the fresh produce regulations is on prevention of microbial contamination of fresh whole produce that may be eaten raw.

Elements of the Rule

The FDA reported that there were 6 key requirements:

- Agricultural water–No detectable level of generic coli would be allowed in water used for hand washing, food contact surface application, ice that is applied directly to produce and for sprout irrigation.

- Biological soil amendments– dealing with Raw Manure (the number of days needed between the applications of raw manure to the soil and harvesting to minimize the risk of contamination) and compost, by setting microbial limits on detectable amounts of bacteria (includingListeria monocytogenes, Salmonella , fecal coliforms, and E. coli 0157:H7).

- Domesticated and wild animals in growing areas- Farmers are required to take all measures reasonably necessary to identify and not harvest produce that is likely to be contaminated.

- Worker training and health and hygiene- Taking measures to prevent contamination of produce and food-contact surfaces by ill or infected persons, using hygienic practices, prevent visitors from contaminating the produce, and training farmer workers on the importance of health and hygiene.

- Equipment, tools and buildings- establishing rules to prevent these as sources of contamination, and providing measures to prevent contamination.

- Sprout Rules- since the product is vulnerable to contamination, there are specific rules associated with it. These rules include taking measures to prevent the introduction of dangerous bacteria, testing irrigation water for certain pathogens, testing the growing, harvesting, packing and holding environment for the presence of Listeria species orListeria monocytogenes.

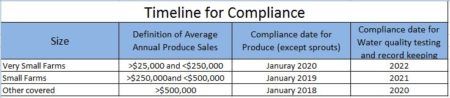

Who Must Comply and When?

The rules apply to producers and packers of raw agricultural products, regardless if they are manufactured domestically or abroad.

Cost of the Farm Rule

The FDA estimates that the annualized average cost per farm of implementing the produce safety rule will be $2,885 for very small farms, $15,265 for small farms, and $28,452 for large farms, which may differ widely within farm size categories depending upon the farm’s current level of compliance. The most likely scenario is that the FDA will pass on many of the implementation costs to state and local governments, who will pass them on to the private sector. Larger enterprises may have a greater capacity to absorb costs, but these costs may be passed on down the supply chain to the final consumers in the form of higher food prices. There is an obvious benefit to these rules: Once these standards are put into action, the incidence of foodborne illness is expected to decrease, as will foodborne outbreaks, and product recalls.

Compliance challenges

Grower needs to keep basic risk assessment in mind at all times: Training:There should be one trained supervisor who receives specialized food safety training with curriculum that is equivalent to what has been approved by FDA. All employees who handle fruit or a food contact surface need to be trained in personal hygiene. The training must occur annually, and documented. This is in industry that did not have training in the past. Knowing the quality of the water: The water needs to be tested and the question is how many times it needs to be tested. A baseline needs to be established first. Be cautious with the use of manure: The time interval until manure can be used is still under investigation. The concern about manure is not just of the farms manure, but also of neighboring farms. Minimize wildlife presence: Limit animal intrusion and check the fields before harvestlng. Contact surfaces: Identify all surfaces that the produce touches as it moves from the field (packing containers, sorting tables, conveyor belts, etc.) until it is loaded on a truck. Cleaning and using the appropriate sanitizers and detergents is a key.