Smart Sensors are Coming and will Improve Food Safety

What are Smart Sensors?

In our previous blog, we described how several new technologies (smart sensors, IoT, blockchain and the cloud) are being combined to make the tracing of food safety better.

In our previous blog, we described how several new technologies (smart sensors, IoT, blockchain and the cloud) are being combined to make the tracing of food safety better.

What is a smart Sensor? It is a device or instrument that takes input from the physical environment and uses built-in computation resources to process data and present it in a more accurate, efficient, and informative way. In most cases, they combine a sensing element with a microprocessor that processes the data and sends it to the user. Lately, smart sensors can also communicate with the internet as part of the Internet of Things (IoT).

Types of Sensors

Time-temperature sensors

Because of their simplicity, low cost, affordability, and efficiency, Time Temperature indicators are widely used. In many facilities, the temperature of incubators, refrigerators, and freezers are automatically monitored, and the data is sent electronically to users. Such system provides unprecedented visibility and traceability, providing temperature data with time and date stamps. The logged data meets 21 CFR Part 11 requirements for electronic recordkeeping, which satisfies the regulatory agencies.

The measures time-temperature during the shipping of produce, providing time and date stamps, and temperature data points, transmitted via Bluetooth. This measurement allows the food company to have instant access to temperature data from anywhere, and alerts are sent immediately if the temperature is out of spec. Having this information allows taking corrective action fast before the problem escalates. The processor also maintains all of its data digitally.

Companies like Monnit and Delta Trak are integrating smart sensors and devices into refrigerators, freezers and the shipping process to create a seamless e-tracking that keeps food cold. The systems provide instant notification via email or text to smartphones or computers.

The disposable, low-cost sensor measures temperature, moisture, and metabolite, and sent the data through wireless communications to the Internet.

Freshness Sensors

Some technologies and companies are providing innovative solutions to produce and other product freshness. Below are a few examples.

Zest Fresh labs provide a freshness management solution to growers, shippers, and retailers. The quality of each pallet of produce is monitored and managed, providing true transparency with real-time, event-driven notifications. To determine the freshness and remaining shelf life, the system calculates the freshness capacity of the product (the total possible shelf life at harvest and dynamically updated based on actual handling and conditions since harvest), and the rate of change of aging for each pallet of product. Wireless IoT temperature sensors are inserted into the pallets at harvest, the product’s condition is monitored and, combined with cloud-based artificial intelligence, machine learning, and predictive analytics dynamically calculates the freshness metric.

FreshSurety uses a low cost, disposable sensor that records and reports each location every ten minutes the data for the temperature, moisture, and metabolite from the time a pallet is assembled in the field to the time it’s broken down at the retailer. Using wireless communication, the sensors data is sent to the internet. The information is converted to product freshness and shelf life assessments at the carton level. A spoilage algorithm (product specific) uses an algorithm that translates the data values into shelf life reports with a quantitative freshness score for each individual cartons and pallets.

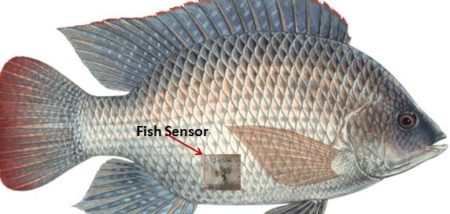

ETH Zurich developed a biodegradable, ultra-thin (thinner than a human hair), micro-sensor to measure that temperature-sensitive products are kept at a temperature that will prevent spoilage. The sensor will completely dissolve in 67 days, and function for a day when submerged in water. The time is sufficient for monitoring fish shipment from Japan to Europe.

ETH Zurich developed a biodegradable, ultra-thin (thinner than a human hair), micro-sensor to measure that temperature-sensitive products are kept at a temperature that will prevent spoilage. The sensor will completely dissolve in 67 days, and function for a day when submerged in water. The time is sufficient for monitoring fish shipment from Japan to Europe.

FoodFresh sensor is very sensitive to gaseous decay products of fruit, vegetables, milk and milk products, fish and meat. For example, the sensor is sensitive to ethanol that is being produced in the fermentation of sugars in fruit and vegetables. Banana release ethylene during ripening; the sensor converts to ethanol. The sensor is also sensitive to amines such as putrescine and cadaverine that are by-products in the spoilage of meat and fish. The sensor has an electrode that is compact, fast responding, low cost, and consumes no power. The sensor results in a go-no-go result. The system sensor reports to the IoT the data of safety, and quality for each individual produce cases anywhere in the world at a few cents per case.

C2Sense developed a small digital odor receptor for the IoT and transferred the smell into data that can be accessed remotely in real time. The C2 solution relies on the development of sensors that can monitor specific volatiles related to spoilage of various food products. Data from the sensor is sent to the cloud, it is processed by a custom algorithm, and a report of gas concentration is sent to the customer’s mobile customers through the interactive web portal.

Intelligent Packaging Sensors

Intelligent packaging sensors are sensors embedded in the food package, showing information about the product quality, monitor interactions between the food, the packaging, and the environment. It is usually a label that is attached to the outside of the container. On package, sensors are an emerging field that is rapidly growing.

Time Temperature sensors

Time-temperature indicators are essential to the quality and safety of refrigerated and frozen foods.

Fresh-check is a self-adhesive sensor that is formulated to match the food shelf-life, attached to the package. The active circle center darkens faster at higher temperatures. As the active center is exposed to temperature over time, it gradually changes color becoming totally dark when the product should not be used. Other similar devices include Timestrip provides clear, irreversible visual evidence and distinct time marking of the thermal abuse phase for dual temperature thresholds.

3M™ MonitorMark™ self-adhesive sensor is showing results indicating both exposure and relative time over which exposure occurred.

Freshness Sensors

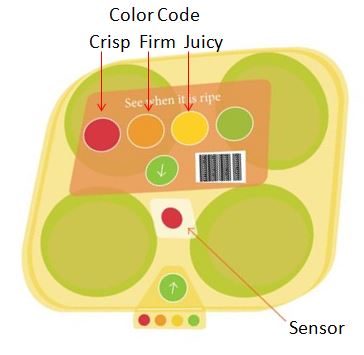

adopted from Ripe Sense

On package freshness sensors typically monitor changes in pH, gas composition in the headspace or other biochemical reaction. The changes are mainly monitored by color changes due to the presence of microbial metabolites. Some examples of freshness sensors:

RipeSense from New Zealand developed the first sensor that changes color due to the ripening of fruits. The sensor works by reacting to the aromas released by the fruit as it ripens. The sensor is initially red, and gradually changes to orange and eventually to yellow.

CheckPack is not yet a product, but a research project. They are developing an optical sensor that can be integrated into food packaging. The purpose is to detect spoilage of food products (through volatile compounds concentrations) and check food packaging integrity (through CO2 and O2 concentrations).

Adopted from Y. Galagan and W. F. Su, 2008

Fadable Ink is widely used in printed labels on food packages as a freshness indicator. The ink disappears as time passes, indicating that the food lost its freshness (Y. Galagan and W. F. Su, 2008. “Fadable ink for time-temperature control of food freshness: Novel new time-temperature indicator,” Food Research International, vol. 41, pp. 653-657). The ink in the label reacts with oxygen that makes the color disappear; the rate of change depends on the chemical composition of the ink.

There are many on-package sensors under development, including a label based on two (methyl red (MR) and bromo cresol purple (BCP)) pH indicators, to monitor the beef freshness. The MR changes its color from red to yellow, while the BCP change its color from yellow to purple. pH changes due to deterioration make the label darker as the meat deteriorate. Another label sensor relies on color changes, related to total volatile amine levels and microbial growth patterns in fish samples. These responses enabled the real-time monitoring of fish spoilage

In a future blog, we will discuss more sensors that are currently available to be connected with IoT.

One response to “Smart Sensors are Coming and will Improve Food Safety”

[…] smart sensors, including time-temperature indicators and freshness sensors, are being integrated into refrigeration and shipping processes to provide instant notifications and ensure the quality of […]